Product Overview

ANRUK pneumatic fittings represent precision-engineered connectivity solutions for industrial compressed air systems. As an ISO 9001-certified manufacturer, we specialize in producing brass, stainless steel, and engineering plastic fittings that meet rigorous DIN/ISO standards, engineered to withstand 15 Bar working pressure and extreme temperature conditions (-40°C to +150°C).

Our product range encompasses 38+ connector types including tube fittings, push-in fittings, quick couplings, and adapters, compatible with NPT, BSPP, BSPT, and metric thread specifications. Designed for seamless integration with pneumatic cylinders, valves, and automation equipment, these corrosion-resistant components feature:

Zero-leak Guarantee with triple-seal technology

Tool-free Installation for maintenance efficiency

Interchangeable Design with SMC/Festo/ Parker legacy systems

With 18 years of OEM/ODM manufacturing expertise, we deliver batch consistency through CNC machining centers achieving ±0.01mm dimensional accuracy. Custom configurations (material/thread/port size) available with 15-day rapid prototyping service.

Why Choose ANRUK Pneumatic Fittings?

Certified Reliability

Leak-proof brass/steel construction with ISO 6150B certification

Extreme Durability

500,000+ cycle endurance tested

Temperature Mastery

-40°C to 150°C operational range

Pressure Optimized

15-bar max working pressure capacity

Universal Compatibility

Interchangeable with major international standards

Related Products

Application Scenarios

Automated Production Lines

Pneumatic Conveying Systems

Robotics & Actuation Systems

Compressed Air Networks

Heavy Machinery Connections

ISO-certified since 2005. Precision pneumatic components for automation and heavy machinery. 50+ patents. Global standards (DIN/ISO/JIS). Trusted by 86 countries.

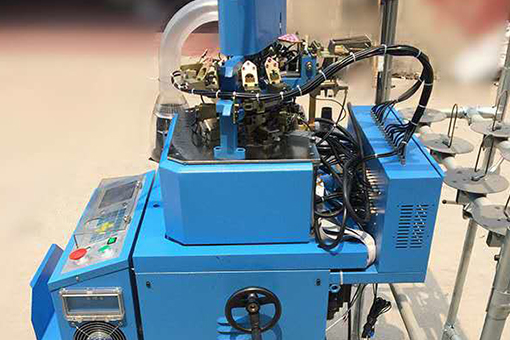

State-of-the-Art Facility

+

Technical Experts

Patented Technologies

Customer Reviews

Alex Müller, Automation Engineer

"Running 15 Bar continuous pressure in our pneumatic conveyors. 200,000+ cycles with <0.5% leakage rate. Their engineering team even optimized port angles for our layout – true partners, not just vendors."

Takashi Ito, Procurement Manager

"Running 15 Bar continuous pressure in our pneumatic conveyors. 200,000+ cycles with <0.5% leakage rate. Their engineering team even optimized port angles for our layout – true partners, not just vendors."

Takashi Ito, Procurement Manager

"Required JIS-B2351 compliant brass fittings for food-grade air systems. ANRUK delivered prototypes in 12 days, full batch within 3 weeks. Their material certification process exceeded JFDA requirements."

Ahmed Al-Maktoum, Project Lead

"From Dubai's 50°C heat to -30°C cold storage projects, ANRUK fittings maintain perfect seal integrity. Local stock in Jebel Ali FTZ cuts lead time to 48hrs – crucial for our EPCC projects."

English

English